Mate Rimac first started Rimac Automobili in 2009 with the dream of building an all-electric hypercar. Now, 15 years later, he has taken delivery of his very own Nevera, the car that wears his name, and represents the very incarnation of his original vision of ultimate performance.

Expectedly, the man who knows every single nut and bolt, length of wire and line of code in the Nevera had a clear concept in his mind for how his car should be personalized. And with the near-limitless options on offer at Rimac Automobili, that vision could be translated from mind to metal and carbon fiber almost perfectly. Almost everything that makes up Nevera is made in-house in Croatia; there’s a machine shop to make intricate metal parts, there’s a paintshop to apply flawless mirror finishes and create a new color altogether, there’s a trimming area and – of course – there’s a design team ready to turn your vision into a reality.

“It’s kind of a crazy experience to be a customer of your own company, and I probably wasn’t the easiest customer either. Just like with all our customers – there was a process of co-creation; sharing ideas, evolving them and then finally perfecting them until you have a Nevera that stands alone and speaks to you personally. The result not only looks great but it tells an important story for me.”

Mate Rimac, Founder and CEO of Rimac Group

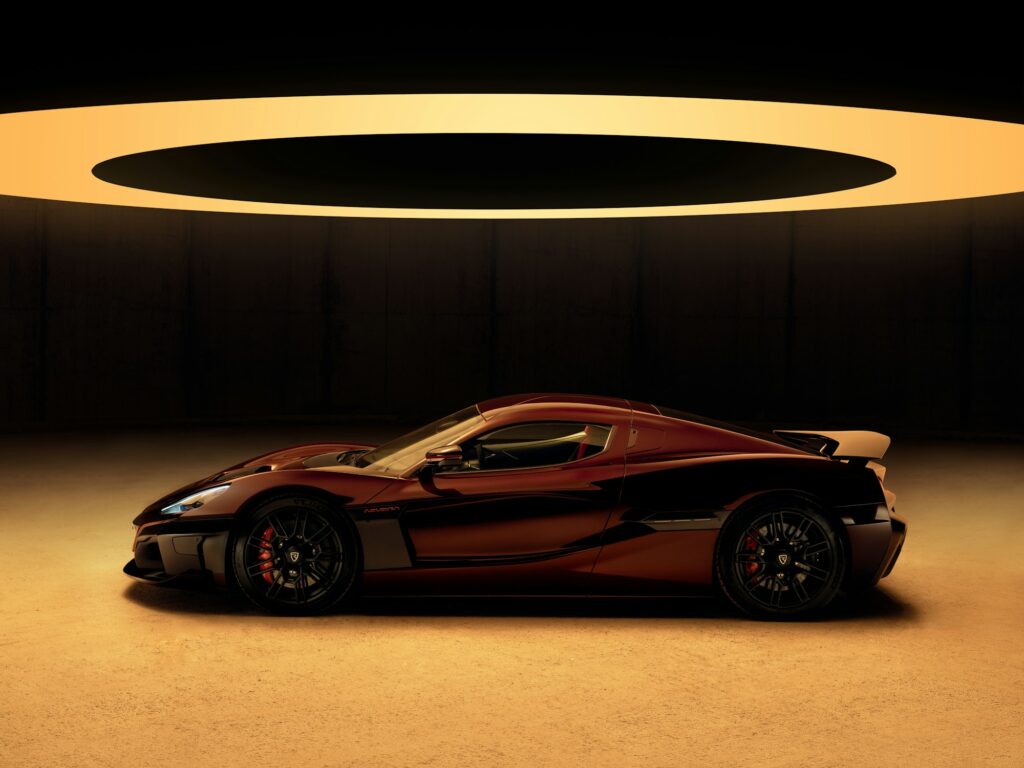

The in-house Color and Trim team had proposed several bespoke liveries and dual-tone finishes – just as they would with every bespoke customer – but Mate decided stayed true to his initial vision: full carbon body tinted in red – complete with Nevera badging bespoke in red anodization – with accents in natural bare carbon fiber. He wanted to show this car’s natural materials in all their beauty.

Much more than simply an unpainted Nevera body, the Level 3 Carbon finish is a completely bespoke creation. The fibers must flow in a very specific direction across the body panels, matching the geometry of the car. And this flow must continue across a number of complex surfaces and neighboring panels to create an unbroken flow of carbon fiber, millimeter perfect in its placement. The panels must be produced and cut in a very specific way to achieve this finish. The process of clear-coating this intricate artwork is quite meticulous; filling any subtle holes in the material with clearcoat can lead it to crack, and the panel will need to be scrapped and the whole process begun anew.

Croatian flags are hand-painted onto the side mirrors and there’s a custom-designed lightning motif hidden under the rear spoiler in homage to the Mediterranean storms off the coast of Croatia that gave Nevera its name. Mate is famously extremely proud of the Rimac Group’s home in Croatia, even refusing to relocate the business within its difficult first years despite the offer of investment.

Inside Nevera’s cabin, bespoke motifs can be hand-stitched into armrests, headrests, knee cushions and more. Special messages can be laser-etched into a metal plate mounted on the bulkhead, and colors and materials are almost endless in their availability. The timeless elegance of a full Napa leather interior, the subtle modernity of an Alcantara and leather mix or even a full Alcantara interior can be applied in a mixture of colors or simply one, highlighted by vibrant stitching. Metal surfaces of the cabin – the door handles, steering wheel buttons and infotainment controls – can all be anodized in a host of different colors to an extent no other manufacturer offers, all because this complex and delicate process could be tested in-house.

For Mate’s car, he has pioneered an asymmetric trim – predominantly black on one side and red on the other. He also opted for a number of personal motifs, including embroidered motifs of Solinjanka – literally, the girl from Solin. This detail is an interpretation of a sculpture of Solinjanka placed in Zagreb ́s Archeological Museum.

Leave a Reply

You must be logged in to post a comment.